OMNIVIEW® GANTRY

MULTI-VIEW, HIGH-ENERGY/DUAL-ENERGY CARGO AND VEHICLE INSPECTION SYSTEM

THE HIGH-PERFORMANCE, HIGH-ENERGY OMNIVIEW SYSTEM PROVIDES BEST-IN-CLASS X-RAY IMAGING.

THE SYSTEM PENETRATES UP TO 400MM OF STEEL AND PROVIDES SUPERIOR QUALITY IMAGES.

High-performance inspection system

AS&E's OmniView Gantry features powerful 4/6 MeV high-energy transmission X-rays that penetrates up to 400 mm (15.7 inches) of steel. The system operates by moving on rails past stationary vehicles and cargo. The bi-directional inspection system scans 28 trucks per hour. The OmniView system can be operated in single-energy mode for optimal penetration.

Ideal for contraband and threat detection at ports, borders, military bases, and other security checkpoints, OmniView Gantry can inspect even the most densely loaded containers. Its unique design minimizes X-ray scatters in order to create a best-in-class, high-quality, detailed X-ray image, displayed on high-resolution monitors.

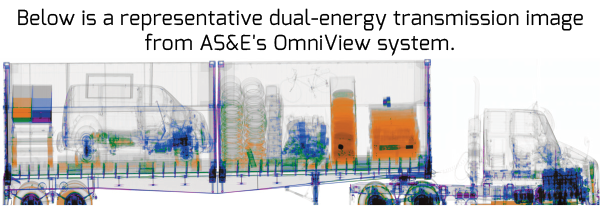

Material Discrimination

The OmniView Gantry dual-energy transmission system generates a high-resolution, colorized image, enabling analysts to visually differentiate classes of materials within uncluttered cargo. Materials are shown in one of four color categories: organics in orange, non-organics in green, metallics in blue, and heavy metals in purple.

Technology

The material discrimination capabilities of AS&E's dual-energy technology enhances operators' ability to differentiate between organic and inorganic threats. Dual-energy imaging is ideal for the detection of metallic components such as weapons, artillery shells, and vehicles borne improvised explosive devices (VBIEDs) as well as organic materials such as drugs and currency.

TECHNICAL SPECIFICATIONS

Operating Features

X-ray Source:

4/6 Mev

High-Energy Mode Penetration:

400 mm (15.7 in) of steel at 0.2m/s

Dual-Energy Mode Penetration:

375 mm (14.7 in) of steel at 0.2 m/s

Wire Resolution

0.8 mm wire in air

Scan Speed:

0.2, 0.3, 0.4 m/s (8,12,16 inches per second)

Throughput:

28 trucks per hour, using 54.86 m (180 ft) of rail and two trucks per scan

Start-Up Time:

Approximately 15 minutes

Crew Requirements:

Scan coordinator and image analyst

Power

50-Hz Systems:

400Y/230V, +/-10%; 100kVA

60-Hz Systems:

480Y V Delta, +/-10%; 100kVA

System Dimensions

Standard Configuration

System Width:

11.07 m (36 ft 4 in)

System Height:

7.7 m (25 ft 2 in)

System Length:

5.3 m (17 ft 3 in)

System Weight:

25.255 kg (55.900 lbs)

Tunnel Width:

3.60 m (11 ft 10 in)

Tunnel Height:

5.10 m (16 ft 9 in)

Tunnel Length Options

36.57 m (120 ft) rails:

Accommodates scanning of one 19 m (62 ft) truck at 0.4 m/s or less

54.86 m (180 ft) rails:

Accommodates scanning of two 19 m (62 ft) truck at 0.4 m/s or less

Maximum Vehicle Dimensions

Width (between rub rails):

3.60 m (11 ft 10 in)

Height:

5.00 m (16 ft 4 in)

Length:

See Tunnel Length Options Above

Radiation Standards:

System conforms to ANSI/HPS N43.3-2008, General Radiation Safety - Installations using non-medical X-ray and sealed gamma Ray sources, energies up to 10 MeV.

Dose to Scanned Vehicle:

Less than 80μSv/scan (5mR) at 0.4 m/s; less than 160μSv/scan (16mR) at 0.2 m/s

Operator Exposure:

Integrated radiation level at the controlled zone boundary is less than 0.5μSv per hour (0.05 mR per hr)

Operating Temperature:

0° C to 131° C (-18° F to 55° F)

Enclosed Facility:

System is designed to be deployed in an enclosed facility to reduce the size of the radiation controlled zone and for other environmental issues.

Operator's Console:

22 in TFT-LCD monitor

Operating System:

Windows 7

Printer:

Color laser printer

CD/DVD Drive

ASEInspection Software

ASEInspection is the Windows-based application software used for system control and image analysis. ASEInspection contains a suite of tools for analyzing images, and it is used for image storage and retrieval.

ASEInspection Features

System Diagnostic Screen:

Real-time system status monitoring screen, which displays the status of the X-ray sources, subsytems, and sensors.

Database Function:

Provides ability to create and store records relating to specific scans

Full Save:

Automatically saves the current image to hard disk when its accompanying database record is saved

Archive:

Manually saves stored image files on a CD or DVD, and creates a reference to the disk in the database.

Export Image:

Provides capability to export full images into TIF/BMP/JPG formatted

Supported Languages:

English, Spanish, Arabic, French, Polish, Russian, Portuguese, and Chinese

Image Analysis Tools

2x20' Segmentation:

Automatically separates two adjacent 20' ISO containers into separate inspection records to be identified and assessed independently

Auto Enhance

Automatically optimizes contrast throughout the image, thereby enhancing subtle differences

Auto Historical Compare (Option)

Presents a side-by-side comparison of a current vehicle image to the same previously scanned vehicle image using vehicle identifier data

Clear/Suspect Tagging:

Tag a record as suspect of having a "threat"

Color Palettes:

Adds the ability to change the image default grayscale values to a palette of colors that correspond to changes in density

Density Expand:

Continuous adjustment of contrast and brightness to emphasize specific densities

High Contrast:

Intensifies subtle differences in contrast by stretching the image histogram

Histogram Equalization:

Adjust the contrast of an image by automatically flattening the image's histogram curve

Mark and Annotate:

Attaches pointers and comment fields to images

Region of Interest:

Allow filters and analysis tools to be applied to a specific, contained area of the images without affecting portions of the image outside the ROI box

Reverse Video:

Reverses the image palette. Normally black areas appear white, while normally white areas display as black

Ruler:

Static and dynamic rulers to allow object measurement

Sharpen:

Accentuates the edges of objects discriminately without accentuating background noise

Show Greyscale:

Toggles iamges between showing all colors or greyscale (dual-energy mode)

Show Metallics:

Display only the objects classified as "High Z-effective" or metallic (dua-energy mode)

Show Organics:

Displays only the objects classified as "Low Z-effective" or organic (dual-energy mode)

Zoom:

1/2 to 16x magnification with the ability to roam continuously through full field of view

Three-Sided Z Backscatter®:

Three-sided Z Backscatter imaging (top-down, left, and right view)

Integrated Container Code Recognition/License

Plate Reader:

Associates data with X-ray images

Integrated Manifest Scanner:

Associates manifest with X-ray images

Integrated Under-Vehicle Inspection System:

Associates under-vehicle picture with X-ray images

Radiation Portal Monitor:

Gamma ray only or gamma/neutron detection

Operator Building:

Climate-controlled operator control room

Camera System:

Three-camera system for observing the area around the X-ray system

Networking:

ASE ConnectTM networking solution provides interconnected remote image analysis and supervisor stations

Transmission Operator-Alert Software

Identifies high-density anomalies

Peripheral Data Interface:

Supplements inspection data with external data (text data fields or images) via a Web-based exchange on the ASEInspection

Radiation Standards:

System conforms to ANSI/HPS N43.3-2008, General Radiation Safety - Installations using non-medical X-ray and sealed gamma Ray sources, energies up to 10 MeV.

Dose to Scanned Vehicle:

Less than 80μSv/scan (5mR) at 0.4 m/s; less than 160μSv/scan (16mR) at 0.2 m/s

Operator Exposure:

Integrated radiation level at the controlled zone boundary is less than 0.5μSv per hour (0.05 mR per hr)

Operating Temperature:

0° C to 131° C (-18° F to 55° F)

Enclosed Facility:

System is designed to be deployed in an enclosed facility to reduce the size of the radiation controlled zone and for other environmental issues.

Operator's Console:

22 in TFT-LCD monitor

Operating System:

Windows 7

Printer:

Color laser printer

CD/DVD Drive

ASEInspection Software

ASEInspection is the Windows-based application software used for system control and image analysis. ASEInspection contains a suite of tools for analyzing images, and it is used for image storage and retrieval.

ASEInspection Features

System Diagnostic Screen:

Real-time system status monitoring screen, which displays the status of the X-ray sources, subsytems, and sensors.

Database Function:

Provides ability to create and store records relating to specific scans

Full Save:

Automatically saves the current image to hard disk when its accompanying database record is saved

Archive:

Manually saves stored image files on a CD or DVD, and creates a reference to the disk in the database.

Export Image:

Provides capability to export full images into TIF/BMP/JPG formatted

Supported Languages:

English, Spanish, Arabic, French, Polish, Russian, Portuguese, and Chinese

Image Analysis Tools

2x20' Segmentation:

Automatically separates two adjacent 20' ISO containers into separate inspection records to be identified and assessed independently

Auto Enhance

Automatically optimizes contrast throughout the image, thereby enhancing subtle differences

Auto Historical Compare (Option)

Presents a side-by-side comparison of a current vehicle image to the same previously scanned vehicle image using vehicle identifier data

Clear/Suspect Tagging:

Tag a record as suspect of having a "threat"

Color Palettes:

Adds the ability to change the image default grayscale values to a palette of colors that correspond to changes in density

Density Expand:

Continuous adjustment of contrast and brightness to emphasize specific densities

High Contrast:

Intensifies subtle differences in contrast by stretching the image histogram

Histogram Equalization:

Adjust the contrast of an image by automatically flattening the image's histogram curve

Mark and Annotate:

Attaches pointers and comment fields to images

Region of Interest:

Allow filters and analysis tools to be applied to a specific, contained area of the images without affecting portions of the image outside the ROI box

Reverse Video:

Reverses the image palette. Normally black areas appear white, while normally white areas display as black

Ruler:

Static and dynamic rulers to allow object measurement

Sharpen:

Accentuates the edges of objects discriminately without accentuating background noise

Show Greyscale:

Toggles iamges between showing all colors or greyscale (dual-energy mode)

Show Metallics:

Display only the objects classified as "High Z-effective" or metallic (dua-energy mode)

Show Organics:

Displays only the objects classified as "Low Z-effective" or organic (dual-energy mode)

Zoom:

1/2 to 16x magnification with the ability to roam continuously through full field of view

Three-Sided Z Backscatter®:

Three-sided Z Backscatter imaging (top-down, left, and right view)

Integrated Container Code Recognition/License

Plate Reader:

Associates data with X-ray images

Integrated Manifest Scanner:

Associates manifest with X-ray images

Integrated Under-Vehicle Inspection System:

Associates under-vehicle picture with X-ray images

Radiation Portal Monitor:

Gamma ray only or gamma/neutron detection

Operator Building:

Climate-controlled operator control room

Camera System:

Three-camera system for observing the area around the X-ray system

Networking:

ASE ConnectTM networking solution provides interconnected remote image analysis and supervisor stations

Transmission Operator-Alert Software

Identifies high-density anomalies

Peripheral Data Interface:

Supplements inspection data with external data (text data fields or images) via a Web-based exchange on the ASEInspection