GEMINI® 6040

DUAL-ENERGY PLUS Z BACKSCATTER® X-RAY INSPECTION SYSTEM

THE GROUND-BREAKING GEMINI SYSTEM SIMULTANEOUSLY DETECTS BOTH METALLIC AND ORGANIC THREATS

EVEN IN CLUTTERED ENVIRONMENTS - FOR MORE COMPREHENSIVE DETECTION THAN TRANSMISSION-ONLY SYSTEMS

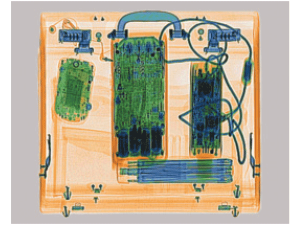

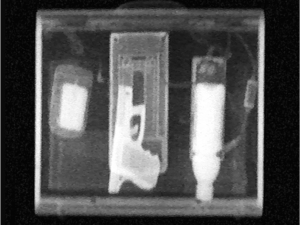

The electronic clutter in the dual-energy transmission image (top) obstructs views of the threats in a briefcase. The Z Backscatter image (bottom) of the same briefcase exposes the Glock handgun and plastic and liquid explosives.

Ground-breaking parcel inspection

AS&E’s ground-breaking Gemini parcel X-ray inspection system combines dual-energy transmission with patented Z Backscatter technology for the most comprehensive threat detection available for parcel, baggage, and mail screening. The Gemini system’s unique capability to detect both metallic and non-metallic threats—even in cluttered environments—makes it an invaluable inspection tool for security officials.

Powerful combination of technologies

The power of the Gemini system lies in its ability to simultaneously detect both inorganic and organic materials by combining dual-energy transmission and Z Backscatter X-rays—two complementary, advanced, and commercially proven technologies. Together, they provide the most information available about the contents of a parcel.

Multi-technology

The Gemini system’s dual-energy transmission X-rays generate a high-resolution image in which metallic threats, such as guns and knives, are easily detected and fine details, such as tiny wires that could indicate an improvised explosive device, can be discerned. Dual-energy transmission technology uses two X-ray energy levels to determine the “effective” atomic number of objects in the parcel and then colorizes the image based on material type.

The Gemini system’s Z Backscatter X-rays generate a photo-like image in which organic materials— such as sheet, bulk, and liquid explosives, narcotics, and plastic weapons—are bright white. The easy-to-interpret images produced by Z Backscatter technology also help to reduce operator fatigue.

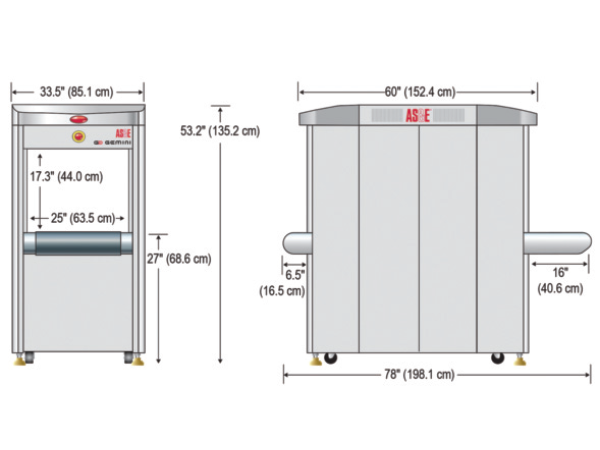

TECHNICAL SPECIFICATIONS

Operating Features

X-ray Sources

Dual-energy source:

140 keV

Z Backscatter source:

160 keV

Tunnel Opening:

Width:

63.5 cm (25 in)

Height:

44 cm (17.3 in)

Length:

Unlimited

Conveyor

Continuous operation in normal mode. Auto-return allows one-person operation.

Width:

63.5 cm (25 in)

Height:

68.6 cm (27 in)

Capacity:

136 kg (300 lbs) distributed

Speed:

23 cm/s at 60 Hz; 20 cm/s at 50 Hz

System Dimensions:

Length:

198.1 cm (78 in)

Width:

85.1 cm (33.5 in)

Height:

135.2 cm (53.2 in)

Weight:

794 kg (1750 lbs)

Transmission beam orientation:

Diagonally upwards

Z Backscatter beam orientation:

Vertically upwards

Portability:

Swivel castors allow convenient relocation of unit. Unit passes through doorways greater than 86.4 cm (34 in).

Temperature

Operating:

0° C to 40° C (32° F to 104° F)

Storage:

-20° C to 60° C (-4° F to 140° F)

Humidity:

5 to 95% relative humidity (non-condensing)

Power:

120 VAC +/- 10%

20 AMP single-phase dedicated line

220/240 VAC +/- 10%

10 AMP single-phase dedicated line 50 Hz/60 Hz

- Two 24-inch 16:9 LED color monitors

- Color printer

- Global power conditioning (Sola Regulator) 50 or 60 Hz

- Steel roller tables (2 ft, 4 ft, 6 ft)

- Stainless steel exit trays (18 in, 3 ft)

- Remote console capability (50 ft, 75 ft, 100 ft)

- Threat Image Projection (TIP)

- Centralized TIP Management

- Computer-based training

- Ergonomic mobile monitor and operator’s console cart Imaging test fixture

- Gamma Radiation Detector

- ASE ConnectTM networking solution

- ASE LearnTM training solution

Operator receives less than 1.0 μSv/hr (0.1 mR/hr) at 5 cm (2 in) from cabinet.

Complies fully with all applicable federal health and safety regulations: Center for Devices and Radiological Health Standards for Cabinet X-ray Systems (21 CFR subchapter J Section 1020.40).

Film-safe.

System Performance

Resolution*:

38 AWG guaranteed, 40 AWG typical

Penetration*:

34 mm guaranteed, 36 mm steel typical

Contrast:

16,000 gray levels visible

Complete coverage of objects in tunnel—no corner cutoff

*Per AS&E test fixtures

Detection Capability

High-resolution dual-energy transmission X-ray provides the ability to detect inorganic “High Z” objects such as guns, knives, and IED wires and provides metallic and organic discrimination in uncluttered environments.

Z Backscatter detects organic “Low Z” objects such as

Operator's Console

User-friendly ergonomic control panel. Two high- resolution displays present separate and simultaneous transmission and Z Backscatter images.

ASEInspection™ Software

ASEInspection is the Windows-based application software used to convert X-ray data into images. It contains a suite of tools for manipulating and enhancing images and is used for image storage and retrieval.

Auto Enhance: Improves resolution of the image by optimizing contrast throughout, thereby enhancing subtle differences in the image.

Color Palette: Adds the ability to evaluate images and areas of interest in greater depth using color. Continuous Zoom: Zooms images to 16x magnification. Density Expand: Adjusts the contrast of the displayed image, thus enhancing the differences in objects.

Edge Enhancement: Accentuates the edges of objects in the image, enabling the operator to recognize objects faster and more readily.

Mark and Annotate: Attaches pointers and comment fields to mark an area of interest in an image.

ASE Frame: Automatically frames areas of high density where X-rays do not penetrate.

High: Changes image contrast so details of high penetration are more defined.

Metallic Stripping: Strips out inorganic material, leaving only those colored orange or green and enabling the operator to better identify organic materials. Organic Stripping: Strips out organic material, leaving only those colored green or blue and enabling the operator to better identify inorganic materials.

View Z: Toggles the image between black-and-white and Zeff -associated colors, allowing the operator to better discriminate different materials in the image.

X-ray Sources

Dual-energy source:

140 keV

Z Backscatter source:

160 keV

Tunnel Opening:

Width:

63.5 cm (25 in)

Height:

44 cm (17.3 in)

Length:

Unlimited

Conveyor

Continuous operation in normal mode. Auto-return allows one-person operation.

Width:

63.5 cm (25 in)

Height:

68.6 cm (27 in)

Capacity:

136 kg (300 lbs) distributed

Speed:

23 cm/s at 60 Hz; 20 cm/s at 50 Hz

System Dimensions:

Length:

198.1 cm (78 in)

Width:

85.1 cm (33.5 in)

Height:

135.2 cm (53.2 in)

Weight:

794 kg (1750 lbs)

Transmission beam orientation:

Diagonally upwards

Z Backscatter beam orientation:

Vertically upwards

Portability:

Swivel castors allow convenient relocation of unit. Unit passes through doorways greater than 86.4 cm (34 in).

Temperature

Operating:

0° C to 40° C (32° F to 104° F)

Storage:

-20° C to 60° C (-4° F to 140° F)

Humidity:

5 to 95% relative humidity (non-condensing)

Power:

120 VAC +/- 10%

20 AMP single-phase dedicated line

220/240 VAC +/- 10%

10 AMP single-phase dedicated line 50 Hz/60 Hz

- Two 24-inch 16:9 LED color monitors

- Color printer

- Global power conditioning (Sola Regulator) 50 or 60 Hz

- Steel roller tables (2 ft, 4 ft, 6 ft)

- Stainless steel exit trays (18 in, 3 ft)

- Remote console capability (50 ft, 75 ft, 100 ft)

- Threat Image Projection (TIP)

- Centralized TIP Management

- Computer-based training

- Ergonomic mobile monitor and operator’s console cart Imaging test fixture

- Gamma Radiation Detector

- ASE ConnectTM networking solution

- ASE LearnTM training solution

Operator receives less than 1.0 μSv/hr (0.1 mR/hr) at 5 cm (2 in) from cabinet.

Complies fully with all applicable federal health and safety regulations: Center for Devices and Radiological Health Standards for Cabinet X-ray Systems (21 CFR subchapter J Section 1020.40).

Film-safe.

System Performance

Resolution*:

38 AWG guaranteed, 40 AWG typical

Penetration*:

34 mm guaranteed, 36 mm steel typical

Contrast:

16,000 gray levels visible

Complete coverage of objects in tunnel—no corner cutoff

*Per AS&E test fixtures

Detection Capability

High-resolution dual-energy transmission X-ray provides the ability to detect inorganic “High Z” objects such as guns, knives, and IED wires and provides metallic and organic discrimination in uncluttered environments.

Z Backscatter detects organic “Low Z” objects such as

Operator's Console

User-friendly ergonomic control panel. Two high- resolution displays present separate and simultaneous transmission and Z Backscatter images.

ASEInspection™ Software

ASEInspection is the Windows-based application software used to convert X-ray data into images. It contains a suite of tools for manipulating and enhancing images and is used for image storage and retrieval.

Auto Enhance: Improves resolution of the image by optimizing contrast throughout, thereby enhancing subtle differences in the image.

Color Palette: Adds the ability to evaluate images and areas of interest in greater depth using color. Continuous Zoom: Zooms images to 16x magnification. Density Expand: Adjusts the contrast of the displayed image, thus enhancing the differences in objects.

Edge Enhancement: Accentuates the edges of objects in the image, enabling the operator to recognize objects faster and more readily.

Mark and Annotate: Attaches pointers and comment fields to mark an area of interest in an image.

ASE Frame: Automatically frames areas of high density where X-rays do not penetrate.

High: Changes image contrast so details of high penetration are more defined.

Metallic Stripping: Strips out inorganic material, leaving only those colored orange or green and enabling the operator to better identify organic materials. Organic Stripping: Strips out organic material, leaving only those colored green or blue and enabling the operator to better identify inorganic materials.

View Z: Toggles the image between black-and-white and Zeff -associated colors, allowing the operator to better discriminate different materials in the image.