SENTRY® PORTAL

HIGH-THROUGHPUT, DUAL-ENERGY/HIGH-ENERGY X-RAY INSPECTION SYSTEM

AT 150 TRUCKS PER HOUR, THE SENTRY PORTAL SYSTEM PROVIDES A HIGH-THROUGHPUT, HIGH-ENERGY, DUAL-ENERGY

MEANS OF SCANNING CARGO WITHOUT COMPROMISING IMAGE QUALITY.

A high-throughput cargo inspection system

AS&E’s Sentry Portal drive-through inspection system provides high-throughput cargo inspection by quickly and safely scanning trucks, cargo containers, and tanker trucks for security screening or Customs enforcement.

With a compact footprint that allows for installation in areas with space constraints, the Sentry Portal system can scan a high volume of containers at seaports, border crossings, and security checkpoints. Using a dual-energy/high-energy transmission X-ray source, it provides excellent penetration—up to 300 mm of steel in high-energy mode—for normal stream of commerce cargo, while minimizing the amount of scattered radiation experienced by the cab—the lowest in the industry. As vehicles pass through the portal, the high-quality images appear in real time on the high-resolution monitor, allowing for immediate processing and analysis. Throughput is up to 150 trucks per hour. A robust container-locating sub-system ensures safe drive-through operation, so that the driver is never exposed to high-energy X-rays. For air cargo screening at airports and other transportation hubs, the Sentry Portal system can scan airport tugs pulling multiple pallets and segment each container into a separate scan record.

Z Portal co-location

For maximum detection capability, the Sentry Portal’s high-energy view can be combined with the multi-view Z Portal®. This allows for three-sided imaging of the entire vehicle (including the cab) and improved detection of organic materials, such as drugs, explosives, and stowaways. For enhanced detection, the system can be easily integrated with radiation detection and container identification systems.

Technology

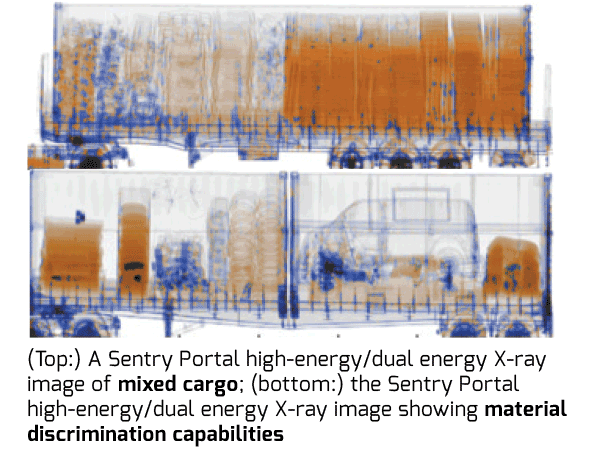

The technology behind the Sentry Portal relies on a dual-energy/high-energy X-ray source, allowing the beam to penetrate dense cargo, while minimizing the amount of scattered radiation. Operable in dual-energy, as well as high-energy, scan modes, the system can provide material discrimination with organic objects colored orange, and metallic objects colored blue. Employing technology to avoid scanning the cab, the container-locating sub-system ensures safe drive-through operations. The sub-system “informs” the X-ray source when the leading edge of the container reaches the beam plane—after the cab with the driver has passed—and in milliseconds, the X-ray beam is switched on. The safety of the drivers and operators is maintained with a robust safety system and very low ambient radiation dose. Extremely safe for operators and cargo alike, Sentry Portal falls well within the radiation safety requirements of NCRP/ICRP.

X-ray Source

7.5/5 MeV

Penetration:

300mm (12 in) of steel in high-energy mode; 280mm (11 in) in dual-energy mode

Wire Sensitivity:

3 mm (0.12 in) in high-energy mode; 4 mm (0.16 in) in dual-energy mode

Scan Speed:

12km/hr (7.5 mph)

Throughput:

Up to 150 trucks per hour

Power:

480 VAC +/- 10% (60 Hz), 3-phase, 20 kVA (U.S.) 380 VAC +/- 10% (50 Hz), 3-phase, 20 kVA (international)

Crew Requirements:

Minimum of one operator

Maximum Vehicle Dimensions:

Transmission beam orientation:

Diagonally upwards

Vehicle Width:

3.0 m (9.8 ft)

Vehicle Height:

5.0 m (16.4 ft)

Overall System Dimensions:

Depth of structure (front-to-back):

3.1 m (10.2 ft)

Width of structure:

8.2 m (27 ft)

Height of structure:

5.8 m (19 ft)

High-Energy Only:

Provides system equipped only with 7.5 MeV source

Air Cargo Scanning:

Allows scanning of air cargo train of ULDs without scanning tug driver and with segment- ing each ULD trailer as a separate inspection record

Z Portal Co-location:

Complements the Sentry trans- mission image with AS&E’s multi-view Z Portal system which offers three Z Backscatter imaging modules for left, right, and top-down views of the cargo

Integrated Container Code Recognition:

Reads the ISO container number via OCR and associates the data with X-ray images in the scan record

Integrated License Plate Reader:

Reads the truck license plates, tractor and/or trailer, and associates the data with X-ray images in the scan record; includes scene camera

Integrated Under-Vehicle Inspection System:

Creates a visual image of the underside of the vehicle and associates it with the scan record

Integrated Manifest Scanner:

Scans paper manifests into electronic format and stores it with the scan record

Driver Scan Activation:

Allows scanning a wider variety of vehicle types by having the driver activate scanning after he has already passed through the inactive beam plane

Camera System:

Three-camera system for observing the area around the X-ray system

Radiation Portal Monitor:

Gamma and gamma/ neutron radiation detection available

Operator Building:

Climate-controlled operator control room

Peripheral Data Interface:

Allows integration of data from third-party devices into system database

Language Kits:

English, Spanish, Arabic, French, Polish, Russian, and Portuguese

Transmission Operator-Alert Software:

Identifies high-density anomalies

Networking:

ASE ConnectTM networking solution provides interconnected remote image analysis and supervisor stations

150 m (500 ft) Operators Kit:

Extends the distance between the Sentry system and the operator’s control station from 30 m (100 ft) to 150 m (500 ft)

System Performance

Operating System:

Windows 7

Operators Console:

High-resolution 21-inch LCD monitor

Printer:

Color Laser Printer

1 TB Hard Drive

Data Storage:

The inspection system is capable of stor- ing more than 130,000 truck images in a standard for- mat. Images can be transferred via a CD-RW or DVD.

ASEInspection Software

ASEInspection is the Windows-based application software used for system control and image analysis. ASEInspection contains a suite of tools for analyzing images, and it is used for image storage and retrieval.

ASEInspection Features

Scan Modes:

High-energy or dual-energy

Automatic Image Segmentation:

Software algorithm segments a multi-container scan image into separately saved image records, including 2x20' trailers and tandem truck trailers

System Diagnostics Screen:

Real-time system status monitoring

Database Function:

Provides ability to create records relating to specific scans

Auto Save:

Automatically saves an image and the associated record of the image as vehicles pass through the screening system, eliminating the need for manual saving

Archive:

Manually saves stored image files on a CD or DVD, and creates a reference to the disk in the database

Export Image:

Provides capability to export full images into TIF/JPG formatted files

Image Analysis Tools

Auto Enhance:

Automatically optimizes contrast throughout the image, thereby enhancing subtle differ- ences in the image

Automatic Historical Compare (Optional):

Based on a user-specified field, the system automatically detects if a vehicle has previously been scanned and presents the prior image in a side-by-side format with the current image.

Density Expand:

Continuous adjustment of contrast and brightness to emphasize specific object densities

High Contrast:

Intensifies subtle differences in contrast by stretching the image histogram

Histogram Equalization:

Adjusts the contrast of an image by automatically flattening the image’s histogram curve

Historical Compare:

Side-by-side comparison of a current image to a saved image

Lock Inspection Records:

Retain specific inspection records that might otherwise be deleted, purged or archived; for use for reference vehicles, training or otherwise notable records.

Mark and Annotate

Attaches pointers and comment fields to images

Color Palettes:

Adds the ability to change the image default grayscale values to a palette of colors that corre- spond to changes in density (high-energy mode)

Region of Interest:

Allows filters and analysis tools to be applied to selected region of image without affecting portions of the image outside the ROI box

Reverse Video:

Reverses the image palette. Normally black areas appear white, while normally white areas appear black

Ruler:

Static and dynamic rulers to allow object measurement

Sharpen:

Accentuates the edges of objects discriminately without accentuating background noise

Show Greyscale:

Toggles images between showing all colors or greyscale (dual-energy mode)

Show Metallics:

Displays only the objects classified as “High Z-effective” or metallic (dual-energy mode)

Show Organics:

Displays only the objects classified as “Low Z-effective” or organic (dual-energy mode)

Suspect Tagging:

Tag a record as suspect of having a “threat”

Zoom:

1/2x to 16x magnification with the ability to roam continuously through the full field of view

Radiation Exposure

Dose to Operator:

Less than 0.5 μSv (50 μR) per hour outside of the controlled zone

Dose to Driver:

Less than 0.006 μSv (0.6 μR) per scan from scattered radiation

Dose to Cargo:

Less than 0.5 μSv (50 μR) per scan

Operating Temperature:

-20°C to 50°C (-4° to 122° F)

Storage Temperature:

-30°C to 55°C (-22° to 131° F)

Operable in rain, snow, wind, and blowing sand

High-Energy Only:

Provides system equipped only with 7.5 MeV source

Air Cargo Scanning:

Allows scanning of air cargo train of ULDs without scanning tug driver and with segment- ing each ULD trailer as a separate inspection record

Z Portal Co-location:

Complements the Sentry trans- mission image with AS&E’s multi-view Z Portal system which offers three Z Backscatter imaging modules for left, right, and top-down views of the cargo

Integrated Container Code Recognition:

Reads the ISO container number via OCR and associates the data with X-ray images in the scan record

Integrated License Plate Reader:

Reads the truck license plates, tractor and/or trailer, and associates the data with X-ray images in the scan record; includes scene camera

Integrated Under-Vehicle Inspection System:

Creates a visual image of the underside of the vehicle and associates it with the scan record

Integrated Manifest Scanner:

Scans paper manifests into electronic format and stores it with the scan record

Driver Scan Activation:

Allows scanning a wider variety of vehicle types by having the driver activate scanning after he has already passed through the inactive beam plane

Camera System:

Three-camera system for observing the area around the X-ray system

Radiation Portal Monitor:

Gamma and gamma/ neutron radiation detection available

Operator Building:

Climate-controlled operator control room

Peripheral Data Interface:

Allows integration of data from third-party devices into system database

Language Kits:

English, Spanish, Arabic, French, Polish, Russian, and Portuguese

Transmission Operator-Alert Software:

Identifies high-density anomalies

Networking:

ASE ConnectTM networking solution provides interconnected remote image analysis and supervisor stations

150 m (500 ft) Operators Kit:

Extends the distance between the Sentry system and the operator’s control station from 30 m (100 ft) to 150 m (500 ft)

System Performance

Operating System:

Windows 7

Operators Console:

High-resolution 21-inch LCD monitor

Printer:

Color Laser Printer

1 TB Hard Drive

Data Storage:

The inspection system is capable of stor- ing more than 130,000 truck images in a standard for- mat. Images can be transferred via a CD-RW or DVD.

ASEInspection Software

ASEInspection is the Windows-based application software used for system control and image analysis. ASEInspection contains a suite of tools for analyzing images, and it is used for image storage and retrieval.

ASEInspection Features

Scan Modes:

High-energy or dual-energy

Automatic Image Segmentation:

Software algorithm segments a multi-container scan image into separately saved image records, including 2x20' trailers and tandem truck trailers

System Diagnostics Screen:

Real-time system status monitoring

Database Function:

Provides ability to create records relating to specific scans

Auto Save:

Automatically saves an image and the associated record of the image as vehicles pass through the screening system, eliminating the need for manual saving

Archive:

Manually saves stored image files on a CD or DVD, and creates a reference to the disk in the database

Export Image:

Provides capability to export full images into TIF/JPG formatted files

Image Analysis Tools

Auto Enhance:

Automatically optimizes contrast throughout the image, thereby enhancing subtle differ- ences in the image

Automatic Historical Compare (Optional):

Based on a user-specified field, the system automatically detects if a vehicle has previously been scanned and presents the prior image in a side-by-side format with the current image.

Density Expand:

Continuous adjustment of contrast and brightness to emphasize specific object densities

High Contrast:

Intensifies subtle differences in contrast by stretching the image histogram

Histogram Equalization:

Adjusts the contrast of an image by automatically flattening the image’s histogram curve

Historical Compare:

Side-by-side comparison of a current image to a saved image

Lock Inspection Records:

Retain specific inspection records that might otherwise be deleted, purged or archived; for use for reference vehicles, training or otherwise notable records.

Mark and Annotate

Attaches pointers and comment fields to images

Color Palettes:

Adds the ability to change the image default grayscale values to a palette of colors that corre- spond to changes in density (high-energy mode)

Region of Interest:

Allows filters and analysis tools to be applied to selected region of image without affecting portions of the image outside the ROI box

Reverse Video:

Reverses the image palette. Normally black areas appear white, while normally white areas appear black

Ruler:

Static and dynamic rulers to allow object measurement

Sharpen:

Accentuates the edges of objects discriminately without accentuating background noise

Show Greyscale:

Toggles images between showing all colors or greyscale (dual-energy mode)

Show Metallics:

Displays only the objects classified as “High Z-effective” or metallic (dual-energy mode)

Show Organics:

Displays only the objects classified as “Low Z-effective” or organic (dual-energy mode)

Suspect Tagging:

Tag a record as suspect of having a “threat”

Zoom:

1/2x to 16x magnification with the ability to roam continuously through the full field of view

Radiation Exposure

Dose to Operator:

Less than 0.5 μSv (50 μR) per hour outside of the controlled zone

Dose to Driver:

Less than 0.006 μSv (0.6 μR) per scan from scattered radiation

Dose to Cargo:

Less than 0.5 μSv (50 μR) per scan

Operating Temperature:

-20°C to 50°C (-4° to 122° F)

Storage Temperature:

-30°C to 55°C (-22° to 131° F)

Operable in rain, snow, wind, and blowing sand